From Quarry to You

At Armstrongs Group, we take pride in being one of the North West’s leading suppliers of high-quality natural stone and aggregates.

With decades of expertise in quarrying and stone processing, we provide materials that support construction, landscaping, and bespoke architectural projects across the UK.

Sourcing stone locally is essential—not only does it ensure superior quality and consistency, but it also reduces environmental impact and supports the local economy. From foundations and driveways to handcrafted stone features, the right materials can make all the difference in durability and aesthetics.

In this blog, we’ll take you through the entire journey of our stone—from the moment it is extracted at our quarries to the processing, shaping, and delivery that brings it to your project.

Our Quarries: Sourcing Premium Stone in the North West

At Armstrongs, we operate five quarries across the North West and Cumbria, each producing unique and versatile stone. These sites allow us to maintain complete control over the quality of our materials, ensuring that every piece of stone meets the highest industry standards.

Our quarries produce a wide range of materials, from durable gritstone and sandstone to the renowned Shap Pink granite. Whether it’s for large-scale construction, landscaping, or bespoke cut stone, each quarry plays a crucial role in supplying the right stone for the right purpose.

Brinscall Quarry: Sandstone with a Legacy

Located near Chorley, Brinscall Quarry has been in operation for over a century, producing a sought-after sandstone that is both durable and visually striking.

This high-quality stone has been used in prestigious projects worldwide, including ongoing work at the Sagrada Familia in Barcelona.

Extracted using traditional methods of blasting and screening, Brinscall sandstone is ideal for building and decorative applications, combining strength with natural beauty.

Montcliffe Quarry: Durable Gritstone for Construction

Situated near Horwich, Montcliffe Quarry has also been operational for over 100 years. It produces gritstone, a hard-wearing, well-cemented sandstone that is widely used in construction.

Thanks to its durability, Montcliffe gritstone is perfect for structural applications, paving, and high-traffic surfaces. Like Brinscall, it is extracted using traditional quarrying techniques, ensuring quality and consistency.

Pilkington Quarry: A Two-Site Legacy

Pilkington Quarry, also near Horwich, is divided into two sections—Pilkington 1 and Pilkington 2. While Pilkington 1 has now been exhausted, it continues to serve as a site for inert waste disposal, playing a key role in sustainable land management.

Pilkington 2, which remains untouched, holds deposits of pale buff/brown gritstone, a highly durable material that will be quarried in the future for construction and architectural use.

Shap Quarry: Home of the Iconic Shap Pink Granite

Nestled in the Cumbrian landscape, Shap Quarry has been producing stone since 1950 and is best known for its Shap Pink granite. This distinctive, high-quality stone is prized for its decorative appeal and strength, making it a popular choice for architectural projects across the UK.

The quarry also produces Light Shap, which is mainly used as aggregate, and Rock Armour, a heavy-duty material used in sea and river defences to protect coastlines from erosion.

Waddington Fell Quarry: A Diverse Sandstone Source

Located near Clitheroe, Waddington Fell Quarry has been operational since the 1960s and is known for its range of high-quality sandstones. The stone from this quarry is not only used for aggregate production but also for cut stone applications, including fireplaces, lintels, and even complete buildings.

By combining strength, versatility, and aesthetic appeal, Waddington Fell sandstone is a popular choice for both traditional and contemporary projects.

Armstrongs’ Product Range: From Raw Stone to Finished Solutions

At Armstrongs, we take pride in offering a diverse range of stone products that cater to various construction, landscaping, and decorative needs.

Whether you’re building a home, enhancing your garden, or working on large-scale infrastructure projects, our stones provide durability, aesthetic appeal, and high-quality craftsmanship.

We source all our stone from our own quarries, ensuring strict quality control and consistency across every product we deliver. Here’s a closer look at the range of products we supply.

High-Quality Aggregates for Construction & Landscaping

Our aggregates are one of the most popular and versatile products in our range. They are essential components in various construction and landscaping projects, offering strength, durability, and reliability.

Whether used in the foundations of buildings, in decorative driveways, or as part of environmental protection systems, Armstrongs aggregates are the perfect choice.

- Crusher Run (75mm): This material is ideal for foundations, providing a solid base for building projects. It’s commonly used for trench fills, sub-base for roads, and as a base layer for driveways and pathways.

- 4mm-20mm Aggregates: These aggregates are suitable for concrete production, as well as for use in driveways and paths. With a range of sizes, they offer versatility in construction and paving projects.

- Rock Armour: A heavy-duty aggregate used primarily in large-scale infrastructure projects, including sea and river defences. Rock Armour provides essential protection against erosion, ensuring the stability of coastlines and riverbanks.

Bespoke Cut Stone for Architectural & Decorative Use

In addition to our aggregate products, Armstrongs specialises in bespoke cut stone designed for both architectural and decorative purposes.

Our expert stonemasons craft precision-cut stone to suit specific client requirements, whether for a heritage restoration, a unique garden feature, or a standout architectural element in modern buildings.

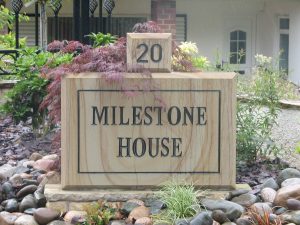

- Custom Stone Features: Our team can create bespoke stone features such as window sills, door surrounds, fence posts, and plaques. These items can add a distinct character to any building or landscaping project.

- Dimensional Stone for Heritage Restorations and Contemporary Designs: We provide dimensional stone for a wide range of applications, including restoration projects for historical buildings and modern design works. This stone is carefully crafted to preserve the aesthetic and structural integrity of both traditional and contemporary properties.

Ready-Mix Concrete: Built on Quality Aggregates

To complement our stone products, Armstrongs produces high-quality ready-mix concrete using the aggregates sourced from our own quarries. This concrete is ideal for a variety of construction applications, from residential builds to large-scale commercial projects.

- Mix Design Options: We offer a range of ready-mix concrete designs, from GEN1 for general use in domestic applications, to RC50 for more demanding projects such as motorway precast concrete. Each mix is tailored to meet the specific requirements of the job.

- Admixtures for Enhanced Durability: To further improve the strength and durability of our concrete, we use admixtures that help adapt to varying environmental conditions. These include liquid retarders to slow the curing process in hot weather, air-entraining agents (AEA) to prevent cracking during freeze-thaw cycles, and accelerator admixtures that ensure rapid strength development within 24 hours.

How We Extract Our Stone: The Quarrying Process

At Armstrongs, the extraction process is carefully planned to ensure that each type of stone is sourced efficiently while maintaining its natural quality. The method we use depends on the intended purpose of the stone—whether it’s being processed into aggregates for construction or precision-cut for bespoke architectural features.

Our team of skilled quarry workers and technicians use both advanced technology and traditional techniques to extract and shape stone that meets the highest industry standards.

Blasting: Efficient Extraction for Large-Scale Aggregates

Blasting is one of the most common techniques used for extracting stone in large quantities, particularly when we need to produce aggregates for construction projects. This method involves the controlled use of explosives to break stone away from the rock face.

How Blast Technicians Prepare and Execute Quarry Blasts

Before any blast takes place, our expert blast technicians prepare the rock face by drilling carefully measured holes in the stone.

These holes are filled with explosives, and everything is set up to ensure a controlled detonation. Once the explosives are in place, the technicians will detonate them from a safe distance, causing the stone to break into manageable pieces.

Uses of Blasted Stone

The stone that is dislodged during the blast is mainly used for aggregates, which are an essential material in construction.

The larger pieces of stone may also be broken down further for use in other applications, depending on the specific needs of the project. Aggregates are used in a variety of applications, including road building, concrete production, and other infrastructure projects.

Manual Excavation: Precision Extraction for Dimensional Stone

When we need to extract stone for more delicate uses, such as dimensional stone or bespoke architectural features, we turn to manual excavation. This method is slower and more precise, ensuring that the stone remains in good condition for later shaping and finishing.

The Role of Excavators and Ripper Attachments

In manual excavation, we use excavators equipped with ripper attachments to carefully remove stone from the quarry face. The ripper attachment works by gently pulling the stone from its natural position, making sure the stone’s integrity is maintained.

Breaking Down Oversized Stone with the Drop Ball Technique

Sometimes, the stone we extract is too large to transport in its raw form. In these cases, we use a drop ball technique to break down the oversized stone into more manageable pieces.

A large metal ball is dropped from a height onto the stone, cracking it into smaller, more usable sections. This method is especially useful when dealing with hard, dense stones that require extra force to break down.

What happens next?

Once the stone is extracted there are a number of different processes that we undertake depending on the finished product.

From Quarry to Product: The Stone Processing Journey

Once the stone has been extracted, it’s ready to be processed into the high-quality products our customers rely on. The processing journey is where raw stone is transformed into the various products Armstrongs offers, whether that’s aggregates, cut stone, or bespoke stonework for architectural projects.

Crushing, Screening & Washing: Preparing Aggregates

The first step in preparing the stone for sale is to process it into aggregates. This involves several steps to ensure that the stone is graded, clean, and ready for use.

Screening to Classify Aggregates by Size

Screening is the first stage of the process, where the stone is sorted by size. This ensures that we can separate the different grades of aggregates for various uses. The material is passed through a series of screens with different-sized mesh to classify it according to its size.

Crushing to Produce Different Grades of Aggregates

After screening, larger stones may be crushed into smaller pieces. Crushing allows us to produce aggregates in a variety of sizes, from fine sand to larger gravel, which can be used for different types of construction and landscaping projects.

Washing to Remove Impurities and Meet Quality Standards

After the stone is screened and crushed, it undergoes a washing process. This is a crucial step, as it removes clay, silt, and other impurities that may have been present in the stone.

The washing process ensures that the aggregates meet quality standards and are suitable for use in construction projects, where purity and consistency are vital.

Saw Cutting: Precision Shaping for Bespoke Stonework

For bespoke stonework, such as dimensional stone for buildings or unique architectural features, precision cutting is essential. At Armstrongs, we use a combination of fixed blade and wire saws to cut the stone into the exact dimensions required.

The Role of Fixed Blade and Wire Saws

Our fixed blade and wire saws are equipped to handle a variety of stone types, cutting them to specific shapes and sizes. These saws ensure that each piece of stone is cut with precision, allowing us to meet our customers’ exact requirements.

Shaping Dimensional Stone for Architectural Applications

Once the stone has been cut, it is carefully shaped to suit its intended use. Whether it’s a window sill, lintel, or decorative stone feature, our saws can produce clean, straight cuts that are perfect for architectural applications.

Hand-Finished Cut Stone: Craftsmanship at Its Finest

For the final step in creating bespoke stone products, our skilled stonemasons apply their expertise to refine and detail each piece. Hand-finishing adds the personal touch that makes our stone products unique.

The Role of Stonemasons in Refining and Detailing

Stonemasons play a crucial role in the final stages of stone processing. They use hand tools to refine and polish each piece of stone, adding intricate details such as chamfers, bevels, and textures.

This craftsmanship ensures that every stone product is not only functional but also aesthetically pleasing.

How Bespoke Stone Is Tailored to Client Specifications

At Armstrongs, we pride ourselves on our ability to customise stone to meet the exact specifications of our clients. Whether you’re building a traditional home or a modern office, we can tailor our stone products to suit your pr

oject’s unique design

From the selection of the stone to the final hand-finishing, every step is carefully managed to create the perfect result.

Armstrongs’ Product Range: From Raw Stone to Finished Solutions

At Armstrongs, we take pride in offering a diverse range of stone products that cater to various construction, landscaping, and decorative needs.

Whether you’re building a home, enhancing your garden, or working on large-scale infrastructure projects, our stones provide durability, aesthetic appeal, and high-quality craftsmanship.

We source all our stone from our own quarries, ensuring strict quality control and consistency across every product we deliver. Here’s a closer look at the range of products we supply.

High-Quality Aggregates for Construction & Landscaping

Our aggregates are one of the most popular and versatile products in our range. They are essential components in various construction and landscaping projects, offering strength, durability, and reliability.

Whether used in the foundations of buildings, in decorative driveways, or as part of environmental protection systems, Armstrongs aggregates are the perfect choice.

- Crusher Run (75mm): This material is ideal for foundations, providing a solid base for building projects. It’s commonly used for trench fills, sub-base for roads, and as a base layer for driveways and pathways.

- 4mm-20mm Aggregates: These aggregates are suitable for concrete production, as well as for use in driveways and paths. With a range of sizes, they offer versatility in construction and paving projects.

- Rock Armour: A heavy-duty aggregate used primarily in large-scale infrastructure projects, including sea and river defences. Rock Armour provides essential protection against erosion, ensuring the stability of coastlines and riverbanks.

Bespoke Cut Stone for Architectural & Decorative Use

In addition to our aggregate products, Armstrongs specialises in bespoke cut stone designed for both architectural and decorative purposes.

Our expert stonemasons craft precision-cut stone to suit specific client requirements, whether for a heritage restoration, a unique garden feature, or a standout architectural element in modern buildings.

- Custom Stone Features: Our team can create bespoke stone features such as window sills, door surrounds, fence posts, and plaques. These items can add a distinct character to any building or landscaping project.

- Dimensional Stone for Heritage Restorations and Contemporary Designs: We provide dimensional stone for a wide range of applications, including restoration projects for historical buildings and modern design works. This stone is carefully crafted to preserve the aesthetic and structural integrity of both traditional and contemporary properties.

Ready-Mix Concrete: Built on Quality Aggregates

To complement our stone products, Armstrongs produces high-qu

ality ready-mix concrete using the aggregates sourced from our own quarries. This concrete is ideal for a variety of construction applications, from residential builds to large-scale commercial projects.

- Mix Design Options: We offer a range of ready-mix concrete designs, from GEN1 for general use in domestic applications, to RC50 for more demanding projects such as motorway precast concrete. Each mix is tailored to meet the specific requirements of the job.

- Admixtures for Enhanced Durability: To further improve the strength and durability of our concrete, we use admixtures that help adapt to varying environmental conditions. These include liquid retarders to slow the curing process in hot weather, air-entraining agents (AEA) to prevent cracking during freeze-thaw cycles, and accelerator admixtures that ensure rapid strength development within 24 hours.

Sustainable & Ethical Quarrying: Armstrongs’ Commitment to the Environment

At Armstrongs, we understand that the extraction of natural stone must be done responsibly to protect the environment for future generations.

That’s why we focus on sustainable quarrying practices that reduce our impact on the land and surrounding areas.

By sourcing all of our stone locally, we significantly reduce the environmental footprint of our materials, ensuring that they reach our customers with minimal energy use and emissions.

Locally Sourced Stone and Its Environmental Impact

By operating quarries across the North West and Cumbria, Armstrongs is able to provide high-quality stone while reducing the need for long-distance transportation.

Locally sourced materials not only support regional economies but a

lso limit the carbon emissions associated with transporting stone from distant locations, making our products a more environmentally friendly choice for construction and landscaping.

Sustainable Quarrying Practices

Our commitment to sustainability extends beyond sourcing. Armstrongs employs responsible extraction methods that prioritise the long-term health of the land.

We carefully plan each quarry’s operations to minimise environmental disruption, ensuring that we only extract the stone that is necessary for production.

Once extraction is complete, we implement effective land restoration plans to return the quarries to a state of natural balance, supporting biodiversity and enabling the land to be used for future purposes.

Ethical Supply Chain & Quality Control

Transparency and quality control are at the heart of our ethical supply chain. Armstrongs ensures that every stone we produce meets our rigorous standards, from extraction to final delivery.

We work closely with our partners and stakeholders to maintain clear communication throughout the process, ensuring that our customers can trust the quality and sustainability of every product they receive.

Bringing Armstrongs’ Stone to You: Transport

& Delivery

Once your stone is ready, Armstrongs ensures that it’s delivered to your site efficiently and on time. We understand the importance of timely delivery, whether you’re working on a small residential project or a large-scale commercial venture.

Our logistics team coordinates transportation to ensure that every delivery is made in a safe, effective, and environmentally friendly manner.

Transport Logistics for Getting Stone from Quarry to Site

We manage the entire transport process to make sure your stone arrives exactly when you need it.

With our fleet of vehicles and experienced drivers, we are equipped to handle deliveries of all sizes. We take care to select the most efficient routes, further minimising our environmental impact by reducing travel distances wherever possible.

Bulk Delivery or Collection Options

Whether you need a bulk delivery of aggregates or a smaller amount of bespoke stone, Armstrongs offers flexible delivery options to suit your project’s scale.

For larger orders, we provide bulk delivery services, ensuring that your materials are delivered in the quantities you need, on schedule.

Alternatively, customers are welcome to arrange for collection directly from our quarries if they prefer to manage transportation themselves.

Timely Supply for All Projects

Armstrongs understands the importance of meeting project deadlines, which is why we prioritise on-time delivery and flexibility.

From small residential builds to large infrastructure projects, we ensure that our stone products are delivered when you need them, allowing your work to progress smoothly without delays.

Whether you need a steady supply of aggregates or a bespoke stone fea

ture for an architectural project, we are here to support you every step of the way.

Ready to start your next project with Armstrongs?

If you’re looking for aggregates, bespoke cut stone, or high-quality concrete, we’re here to help. Get in touch with our team today to discuss your requirements or place an order.

Read More